|

|

|

|

Breaking Down the Walls

By Craig Cochran

Although it saves money and promotes flexibility,

process orientation means losing those cherished, autonomous departments.

For most organizations, process orientation offers one of the

biggest improvement opportunities available. It also represents a huge

change in the way most organizations view and manage themselves. With

process orientation, organizations think in terms of integrated processes

rather than a confederation of functional departments. Although there's

nothing inherently wrong with managing by departments, problems arise

when they're managed semi-autonomously. In such cases, each department

manager attempts to maximize his or her results without considering how

the results affect the remaining portions of the process. In addition,

departmental divisions cause countless problems related to communication,

coordination and resources. As a result, the organization's performance

suffers because its operations aren't structured optimally.

What's in a process?

Before we go further, let's clarify what the term "process"

means. Very simply, a process is an activity, or bundle of activities,

that takes inputs and transforms them into products or output. Under this

extremely broad definition, just about any activity could qualify as a

process. However, we'll concern ourselves strictly with major business

processes -- the handful of primary transformation activities within an

organization. Even the most complex organization probably has fewer than

20 major business processes. These work together in an integrated manner

to carry out the organization's strategy and achieve its mission.

Managing a business in terms of business processes makes perfect sense,

you might be thinking. Why would an organization manage itself any other

way? The answer is that most organizations are structured according to

functional activities rather than processes. For example, people who perform

similar activities and report to the same manager are grouped together.

Once they finish their work, the product is handed off to the next functional

department and forgotten.

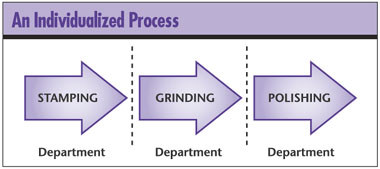

For example, consider the manufacture of widgets. The three key activities

in widget manufacturing are stamping, grinding and polishing. A traditional

widget manufacturer divides these activities into individual departments,

each with its own manager, staff, equipment and supplies, as illustrated

below.

|

From one perspective, organizing the company like this makes a lot of

sense. The work is cleanly divided into discreet activities, with specialists

doing their jobs and only their jobs. Measuring the output of individual

activities is easy. At the beginning of the 20th century, Frederick Taylor

and Henry Ford used this approach to achieve new levels of productivity

from, and control over, employees. With cleanly divided departments, employees

are focused on their own work and little else.

Ironically, this focus is also one of the drawbacks of the approach. Everyone

concentrates exclusively on his or her job and really doesn't understand

how the work contributes to the organization's greater goal. Departments

try to excel individually without regard to the organization's overall

excellence. Each department measures its output and its efficiency, doing

whatever it can to improve this performance. Such a structure works fairly

well when an organization makes a large quantity of a few products and

it can sell everything it makes. The structure causes problems, however,

when the product list expands and mass customization becomes critical.

Of course, a wide product list and mass customization are virtually the

norm now, for manufacturer and service providers alike.

Another drawback to the departmental approach is that resources aren't

easily shared across departments. Personnel are trained to do jobs in

their departments only; they can't be redirected to activities in other

departments because they don't know anything about those activities. Even

if they did, what would be the advantage to the department manager, who's

measured on the output of his or her department? The departmentally structured

organization lacks the flexibility to apply people where they're needed

on a moment's notice.

Personnel aren't the only resources that get snagged on departmental boundaries.

Supplies and materials don't flow easily across these divisions either.

When supplies and materials are allocated to individual departments, there's

little motivation to share resources when other departments need them.

At the very least, delays occur as the details are worked out and managers

determine how they can benefit from the situation. The question, "What

do you have that I can use?" is often heard in such situations. Because

most managers are compensated based on their department's performance,

they can't be blamed for behaving logically.

The last important resource that has trouble passing through departmental

boundaries is information. The departmental structure sets up a filter

between information and the people who need to receive it. Feedback about

the conformance of work between departments is delayed or blocked altogether.

In many organizations, it's forbidden for personnel to leave their departments

and interact with people from other departments. Even without such explicit

prohibitions, though, departmental divisions pose an obstacle to personnel

receiving feedback on their work further down the line. This block reinforces

the tendency for departments to think of themselves as little islands,

operating independently of other activities.

Orienting to the big picture

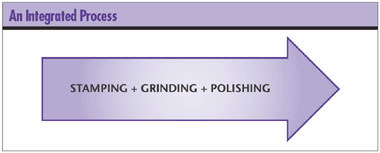

Consider how the illustration below differs from the one we've

been discussing.

|

The functional activities of stamping, grinding and polishing are recognized

as part of an overall process. No departmental boundaries exist between

these activities. Personnel are cross-trained on different jobs so they

can move from one activity to the next, based on the workload. Flexibility

is built right into the structure. Because departmental boundaries don't

exist, resources also flow smoothly from activity to activity. Information,

supplies and materials all go where they're needed, when they're needed.

One person manages the entire process and is compensated based on the

process's overall performance, rather than just one aspect of it.

An organizational structure based on major processes makes perfect sense,

but it's a radical departure for many enterprises. Most managers have

come of age in a world where companies consisted of functional departments,

not integrated processes. Understanding how processes function requires

a different mindset than understanding how departments function.

The missing element here is the link between one activity and the next.

In functional departments, links are taken for granted. If each department

does its part, then the entire organization will succeed. Little consideration

is given to the links between the departments, even though most problems

occur there.

Process orientation highlights the links between activities because the

links have become a visible part of the process. They aren't disguised

by departmental boundaries. With true process orientation, if the links

aren't effective, it becomes immediately apparent. The connections between

activities become smoother because the process's dynamic nature demands

that they continually improve.

Clear processes also encourage organizations to use teams in the workplace.

Supervision is important when people must be pushed and directed, which

happens when nobody really understands how the overall process works.

In an organization that has adopted process orientation, everybody can

clearly see how the various activities fit together and support one another.

The relationships are obvious. People can see and understand the results

of their efforts, and supervision becomes less necessary. Process orientation

therefore promotes self-directed work teams and team problem-solving.

In almost every way, process orientation is superior to traditional departmental

structure. Consider the following comparison between a functional department

and an integrated process:

• Specialization

• Improvement efforts focused on the activity level

• Each activity fully staffed

• All personnel and equipment utilized

• Little understanding of interdependencies between activities

and processes

• Close supervision

• Localized communication

• Slow feedback from downstream activities

• Metrics focused on the activity

• Narrow accountability

• Little flexibility in the event of changes

• Competition for resources

• An inward-looking view

• Clean divisions between management and staff

• Broad competencies

• Improvement efforts focused on the process level

• Activities only staffed as necessary

• Personnel and equipment used when demand requires them

• Heightened understanding of interdependencies between activities

and processes

• Less need for supervision

• Free-flowing companywide communications

• Fast feedback from downstream activities

• Metrics focused on the overall process

• Broad accountability

• Flexibility when change occurs

• Shared resources

• An outward-looking view

• Blurred divisions between management and staff

Typical business processes

Many sub processes support one major business process, but they

all have the same ultimate objective: enabling the business process to

fulfill its organizational objective. Major business processes sometimes

coincide with traditional departmental boundaries but more often cut across

them.

People often become confused about where to draw the lines between major

processes. It's worth vigorous discussion but not worth getting too hung

up on. The exact definition of each business process could easily be argued

from a number of different angles. It's important to remember that, with

process orientation, the organization is broadening its focus and attempting

to embrace a new structure. This alone is a huge breakthrough.

Let's look at some examples of major business processes and the sub processes

that support them.

| Leadership process: |

| |

• |

Determining a mission |

| |

• |

Developing a strategy |

| |

• |

Selecting key measures |

| |

• |

Communicating the mission, strategy and key measures |

| |

• |

Ensuring that all processes stay focused on the customer |

| |

• |

Analyzing data |

| |

• |

Making rational decisions |

| |

• |

Recognizing personnel for their contributions |

| |

• |

Representing the organization to the outside environment |

| |

• |

Acting ethically |

| Customer satisfaction process: |

| |

• |

Conducting research into market needs and desires |

| |

• |

Communicating market needs and desires to other processes |

| |

• |

Developing the marketing strategy |

| |

• |

Locating potential customers |

| |

• |

Providing product information |

| |

• |

Selling |

| |

• |

Performing sales follow-up |

| |

• |

Gauging customer perceptions |

| |

• |

Analyzing data on customer perceptions |

| |

• |

Communicating to the organization about customer perceptions |

| Design process: |

| |

• |

Understanding market needs and desires |

| |

• |

Converting needs and desires into design input |

| |

• |

Planning design activities |

| |

• |

Coordinating activities with all process leaders |

| |

• |

Developing product output that meets design input |

| |

• |

Reviewing the design progress |

| |

• |

Verifying and validating design output |

| |

• |

Communicating design information to other processes |

| |

• |

Controlling design documents |

| Inbound process: |

| |

• |

Communicating needs to suppliers |

| |

• |

Evaluating and selecting suppliers |

| |

• |

Purchasing supplies, services and equipment (i.e., inbound products)

|

| |

• |

Verifying the conformity of inbound products |

| |

• |

Ensuring the payment of suppliers |

| |

• |

Providing feedback to suppliers on performance |

| |

• |

Moving inbound products to the appropriate location |

| |

• |

Storing inbound products as necessary |

| |

• |

Optimizing the time, cost and performance of inbound products |

| Product realization process: |

| |

• |

Communicating supply, service and equipment needs to inbound process

|

| |

• |

Scheduling work |

| |

• |

Arranging resources |

| |

• |

Producing the product through appropriate transformation activities

|

| |

• |

Verifying product conformity |

| |

• |

Providing feedback to all activities within the process |

| |

• |

Packaging the product as appropriate |

| |

• |

Applying identifiers to the product as appropriate |

| |

• |

Final product release |

| Outbound process: |

| |

• |

Handling of the final product |

| |

• |

Scheduling transportation |

| |

• |

Storing the product |

| |

• |

Ensuring preservation |

| |

• |

Order picking |

| |

• |

Truck loading |

| |

• |

Coordinating delivery with customers |

| Personnel management process: |

| |

• |

Determining personnel competency needs in cooperation with process

leaders |

| |

• |

Recruiting appropriate personnel |

| |

• |

Assigning personnel to processes |

| |

• |

Determining appropriate compensation and benefits packages |

| |

• |

Developing policies that result in employee retention |

| |

• |

Facilitating organizational communications |

| |

• |

Mediating conflict |

| |

• |

Ensuring legal compliance |

| |

• |

Administering programs to build competencies (e.g., training, etc.)

|

| Maintenance process: |

| |

• |

Providing maintainability requirements to inbound process

owners |

| |

• |

Determining and implementing preventive maintenance |

| |

• |

Scheduling work in the most efficient manner possible |

| |

• |

Reacting to breakdown scenarios |

| |

• |

Performing predictive maintenance |

| |

• |

Optimizing infrastructure cost, timing and effectiveness |

| Improvement process: |

| |

• |

Guiding the development of procedures |

| |

• |

Managing internal audits |

| |

• |

Administering corrective and preventive action |

| |

• |

Reporting to leadership on the results of improvement efforts |

| |

• |

Facilitating problem-solving methods and tools |

| |

• |

Troubleshooting with customers |

| |

• |

Assisting in improving suppliers |

| |

• |

Guiding the use of statistical techniques |

| |

• |

Identifying and removing nonvalue-added activities |

| |

• |

Soliciting improvement ideas from personnel |

| |

• |

Ensuring personnel recognition |

| |

• |

Supervising the investigation into product and service failures

|

Drawing the lines between business processes is something of a balancing

act. Generally, an organization benefits when the business process cuts

as broadly as possible through the organization: however, a process that

cuts too broadly will be difficult to control. Defining the end of one

business process and the start of another is a matter of subjective judgment

and what can only be called "process wisdom." Nevertheless,

a couple of guidelines can assist in defining the processes.

First, business process includes activities that add value to a product

in the same general manner (e.g., by acquiring and readying the product,

transforming the product, etc.). The activities don't necessarily need

to be similar to one another, but they must work toward a common destination.

Second, business process includes activities that have the same general

objective (e.g., acquiring the best supplies and materials at a competitive

cost, transforming the product in the most efficient manner possible,

etc.).

Avoid the temptation to define processes along the same boundaries as

functional departments. The whole point of process orientation is to combat

the narrow, myopic perspectives that functional departments often encourage.

Simply calling a functional department by a different name does nothing

for the organization.

Beginning the journey

In a perfect world, restructuring an organization along business processes

would be a simple action. Nobody resides in a perfect world, however.

Organizational changes of this magnitude carry with them significant implications,

and usually only the most senior managers can successfully carry them

out. Even then, they sometimes fail.

Evolving toward process orientation is the best solution. Practical actions

can be implemented that will gradually shift your organization toward

process orientation. And these can be implemented by anyone with organizational

respect and clout. The cumulative impact of the following actions is great,

but taken slowly and incrementally, they're much easier to digest:

| • |

Determine the business processes that exist within the

organization. |

| • |

Compare the boundaries of the business processes with existing functional

departments to determine where conflict exists. |

| • |

Develop process flow diagrams that span departmental boundaries

and depict business processes in their entirety. |

| • |

Cross-train personnel who work within the same business process. |

| • |

Assign cross-trained personnel to new activities in order to build

flexibility and heighten awareness of the integrated process. |

| • |

Examine incentives and objectives across functional departments.

Do they encourage improved functional departments at the expense of

business processes? Remove all incentive and objectives that suboptimize

the organization's overall performance. |

| • |

Establish opportunities for personnel to interact within and across

business processes. Encourage frequent dialogue. Some of the best

improvement ideas come serendipitously through informal discussion.

|

| • |

Encourage personnel to communicate their ideas for improvement.

Focus personnel on improving business processes rather than narrow

tasks and activities. |

| • |

Eliminate activities that don't add value or contribute to the effective

functioning of the business process. |

| • |

As personnel and managers become accustomed to thinking in terms

of business processes instead of functional activities, begin reshaping

the formal structure of the organization toward process orientation.

|

Craig Cochran |

About the Author:

Craig Cochran is a project manager with the Center for International

Standards & Quality, part of Georgia Tech's Economic Development

Institute. He's an RAB-certified QMS lead auditor and the author of

Customer Satisfaction: Tools, Techniques and Formulas for Success

and The Continual Improvement Process: From Strategy to the Bottom

Line, both available from Paton

Press. CISQ can be reached at (800) 859-0968 or on the Web at

www.cisq.gatech.edu. |

|

The Continual Improvement Process: From Strategy to the

Bottom Line

Continual improvement is not optional. It is a condition of survival.

Every organization must have systematic methods for making smart decisions,

attacking problems, improving its products and services, and repelling

competitors. Anything less than a systematic, disciplined approach

is leaving your future in the hands of chance. This book presents

a range of practical methods for driving continual improvement throughout

the organization. The starting point is leadership, with a clear definition

of mission, strategy, and key measures. These themes are then carried

throughout the enterprise, informing everyone on the issues that matter

most to survival and success. Strategic approaches for the deployment

of metrics, review of organizational performance, effective problem

solving, internal auditing, process orientation, and cultural development

are also described in detail. Practical tools and examples are provided

at every step of the way, enabling immediate implementation of the

concepts. This book is more than a guide to continual improvement;

it is a guide to leading and managing any organization. |

|

Buy

Amazon

|

Customer Satisfaction: Tools, Techniques and Formulas

for Success

Customer satisfaction is the single most important issue affecting

organizational survival. Despite this fact, most companies have

no clue what their customers really think. They operate in a state

of ignorant bliss, believing that if their customers were anything

less than 100-percent satisfied they'd hear about it. Then they

are shocked when their customer base erodes and their existence

is threatened. The key to competitive advantage is proactively gauging

customer perceptions and aggressively acting on the findings. The

techniques for doing this don't have to be difficult, they just

have to be timely and effective. This book explores a range of practical

techniques for probing your customers' true level of satisfaction.

Tools and specific instructions for use are described in detail,

enabling the organization to get started immediately. The tools

range from very basic to highly sophisticated, providing a path

for organizations to follow as they progressively become more familiar

with the unique drivers of customer satisfaction. This is the perfect

reference for organizations that want to continually improve and

outpace their competition.

|

top of page |

|